Aerospace and Aviation

Reduce cleaning time while increasing the lifespan of your tooling and equipment

ICEsonic dry ice blasting process is ideal for removing paint, decals, dirt, grease, oils from landing gear and the outer hull of aircraft. Also, it can remove rubber skid marks, burnt carbon deposits, engine exhausts, wheel wells, and adhesives from floor panels of aircraft. ICEsonic dry ice cleaning can be used on and around bearings, machined surfaces, moving parts, painted surfaces, electrical equipment, glass, or any sensitive area.

Examples

· Turbine Blades

· Paint

· Skid Mark Rubber Removal

· Oil and Grease

· Aircraft Hulls

· Landing Gear Systems

Aerospace and Aviation

Surface Preparation

Treat surfaces so they are clean, dry, oil free and ready for further treatment

ICEsonic’s dry ice blasting removes contaminants and build up without any change to the targeted surfaces. Dry ice blasting can be safely performed on a variety of surfaces. Treated surface will remain chemically clean, dry, oil free and ready for further treatment. Dry ice blasting leaves no residue and increases the efficiency of your work.

Recommended Products

Aerospace and Aviation

General Equipment Cleaning

Increase the efficiency and lifespan of your equipment while saving time

Dry ice blasting is a fast and safe way to maintain all types of equipment. ICEsonic’s dry ice blasting is a completely dry cleaning process that is safe for all electrical components on your equipment. It allows you to clean in-place without cooldown or disassembly. Dry ice blasting is a non-abrasive, non-conductive cleaning method that is safe for the surface of your equipment. It will not create additional harmful waste.

Recommended Products

Aerospace and Aviation

Rubber Mold Cleaning

Increase the lifespan of your rubber molds and improve product quality

ICEsonic dry ice blasting system enables you to remove the buildup of material and release agents that will cause change in mold geometry. Dry ice cleaning method does not require cooldown of the press or disassembly. This way you can avoid reassembly damages and save time. Non-abrasive properties of dry ice allow frequent maintenance and longer tooling lifespan, at the same time the scrap rate is reduced. Dry ice blasting is a fast and effective cleaning method that reduces cleaning time and labor costs up to 80%.

Recommended Products

Aerospace and Aviation

Operational Equipment Cleaning

Clean machines and electronics during operation to reduce downtime

Dry ice blasting is faster and more effective way of cleaning your operational equipment. ICEsonic dry ice blasting system enables you to remove the buildup from your equipment reducing the risk of breakdown without damaging surfaces. This cleaning method is non-abrasive, does not create secondary waste and is environmentally friendly. It improves preventative maintenance as well as inspection processes. Using ICEsonic dry ice blasting you will note reduction in production downtime and unplanned maintenance.

Recommended Products

Aerospace and Aviation

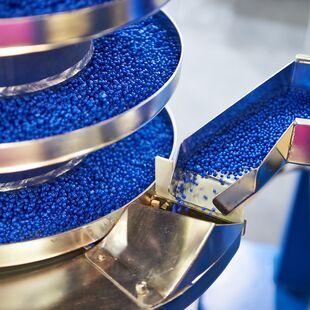

Plastic Injection Mold Cleaning

Increase the quality and lifespan of your plastic injection molds

ICEsonic dry ice blasting is a fast, effective and non-abrasive way of cleaning. Due to the dry ice blasting technology, mold cleaning can be performed on an operational mold press at operating temperatures. It is used to clean extruder screws, dies and casts, ovens, mixers, molds and other plastic injection equipment. Dry ice blasting will improve operational efficiency, quality parts and reduce costs.

Recommended Products

Aerospace and Aviation

Composite Tool Cleaning

Safer cleaning of your composite tools with no damage to geometry or dimensions

ICEsonic’s dry ice blasting will not change the dimensions or geometric shape of parting lines and sealing surfaces due to its non-abrasive properties. This way your composite tools and molds will have 5-10 times longer life span. With ICEsonic dry ice blasters you will have up to 70% reduction in cleaning time.

Recommended Products

Dry Ice Blasting Benefits

Dry ice blasting safely removes contaminants from the surface. Due to non-abrasive properties of dry ice this cleaning method meets aerospace industry demands. Dry ice blasting leaves the surface dry and ready for painting preparation or safety inspections.

· Non-abrasive

· No disassembly required

· Cleaning in-place

· Employee and environmentally safe

· Reduction of waste

· Doesn’t create secondary waste

How Can We Help?

Our team is happy to answer your questions. Fill out the form and we'll be in touch as soon as possible.